Design

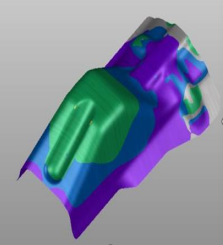

Form Simulation(CAE)

For complex shapes parts, we will conduct CAE simulation in the design process, review and confirm the possible risks and problems in the forming process, then let customers to confirm, and give possible improvement suggestions, so that customers can know the risks in advance and optimize the part plan.

Development and design process

In the tooling development and design process, we understand customer needs in time, and give customers suggestions based on years of rich actual experience, effectively helping customers avoid the risks in advance and save cost and time.

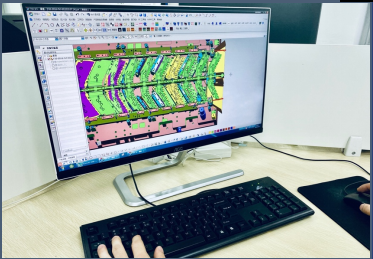

Strip layout design and tool design confirmation

Submit the 3D strip layout within 2 working days after receive the data, and submit the mold structure drawing within 5 working days.Provide highly competitive tools in efficient time.

Design advantage

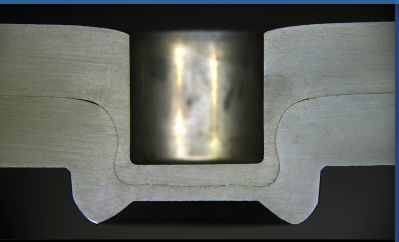

*All designers have more than 10 years of rich experience in the industry.

Familiar with the forming of deep-drawn parts, and can correspond to the tool design of riveting, tapping and complex forming parts.

We can correspond to the different material part of progressive tool

Such as: parts with a thickness of 0.8 ~ 6.0mm; high-strength steel parts up to 1180; stainless steel parts;aluminum parts; copper parts, etc.